Hitork Gears & Drives

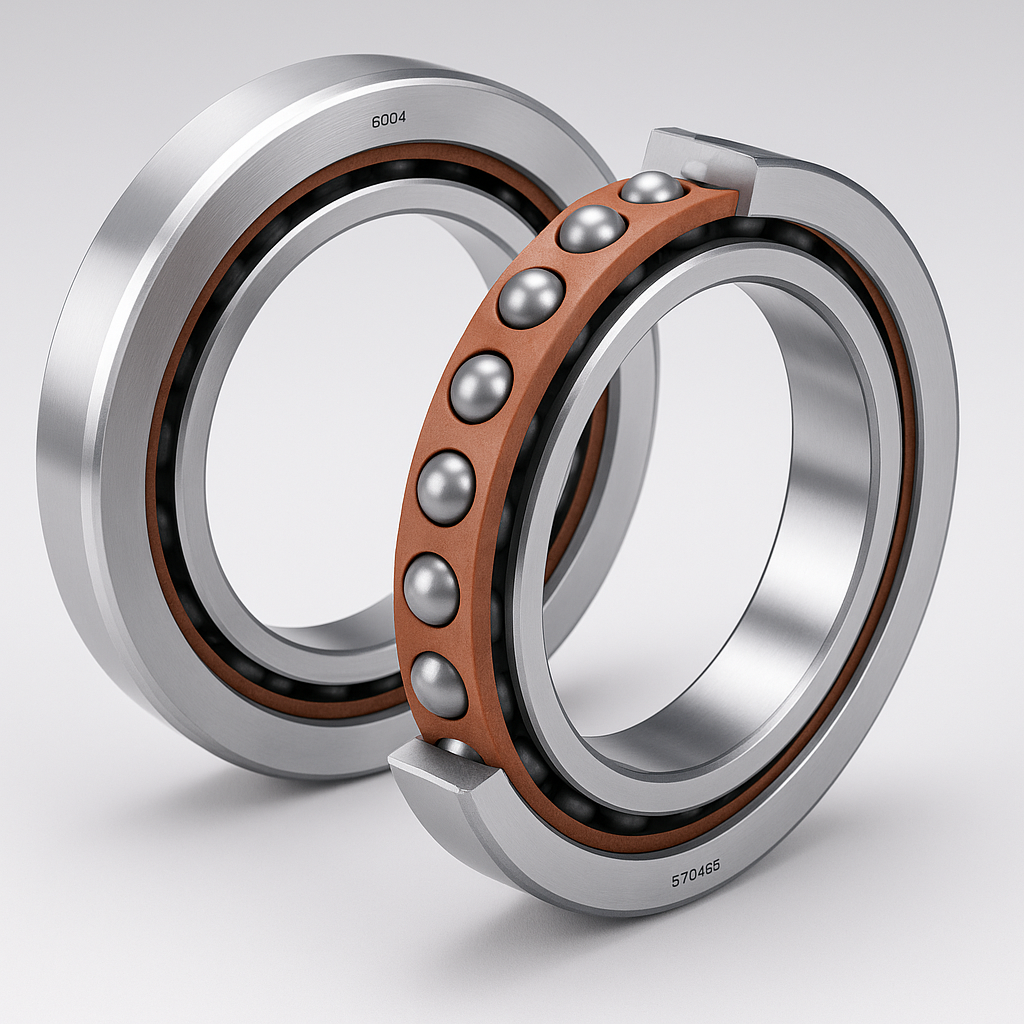

Ultra High Speed Angular Contact Ball Bearings - BNR Series (Part # Starting 65-85)

Ultra High Speed Angular Contact Ball Bearings - BNR Series (Part # Starting 65-85)

Couldn't load pickup availability

bearing designed for applications that require extremely high rotational speeds and a high degree of stiffness, such as machine tool spindles. The "BNR" designation indicates a specific series with an 18° contact angle, which is optimized for high-speed performance.

Key Features and Characteristics ⚙️

The BNR series is part of the ROBUST Series of bearings developed by manufacturers like NSK. They are engineered to overcome the challenges of high-speed rotation, which include heat generation, thermal deformation, and reduced service life.

-

Ultra High Speed: These bearings are specifically designed for high-speed operation, often capable of speeds that are 20% to 80% higher than conventional precision angular contact bearings.

-

Low Heat Generation: An optimized internal structure and advanced materials help to minimize friction and heat, which is crucial for maintaining the bearing's precision and longevity at high speeds.

-

High Rigidity: BNR bearings are often used in duplex (paired) or multi-bearing arrangements (e.g., back-to-back, face-to-face) to provide high rigidity and support for both radial and axial loads.

-

Material Variations: The bearings are available in different material configurations to suit various performance requirements.

-

S-type: Features steel balls and rings, offering a cost-effective option for high-speed applications.

-

H-type: Features ceramic balls (silicon nitride, Si3N4) and steel rings, which results in even lower heat generation and higher speeds.

-

X-type: Features ceramic balls and rings made from SHX steel, a specialized material with excellent seizure and wear resistance, allowing for even higher speeds and longer life.

-

-

Lubrication: The choice of lubrication is critical for these high-speed bearings. They can be used with grease lubrication at speeds where conventional bearings would need an oil-air system, and certain types (like the Spinshot™ XE) use a proprietary oil-air lubrication system to achieve speeds exceeding 2 million dmN.

-

Preload and Precision: BNR bearings come with a specified preload (e.g., extra light, light, medium) and high precision ratings (e.g., P3 or P4), which are essential for achieving the required running accuracy and rigidity in a spindle.

Applications 🛠️

The unique features of BNR series bearings make them ideal for applications that demand high-speed, high-precision, and reliable operation.

-

Machine Tool Spindles: This is the primary application for BNR series bearings. They are used in the main spindles of high-speed machining centers and grinding machines, where they enable faster cutting speeds and improved surface finish.

-

High-Speed Motors: The bearings are also used in high-speed electric motors and other rotary equipment where low vibration, low noise, and high speeds are required.

-

Other Industrial Machinery: Their ability to handle combined loads and operate at high speeds makes them suitable for various industrial applications, including certain types of pumps, compressors, and automation equipment.

Please contact Rohima for dispatch related questions 9916202500

Freight Extra